Cadia Chillers Upgrade Project

Cadia produces Gold & Copper through crushing, grinding and flotation circuits. The grinding circuits comprise several large mills which are cooled by stand alone chilled water systems. These systems had degraded with age and cooling was being supplemented by temporary hire chillers which was not sustainable.

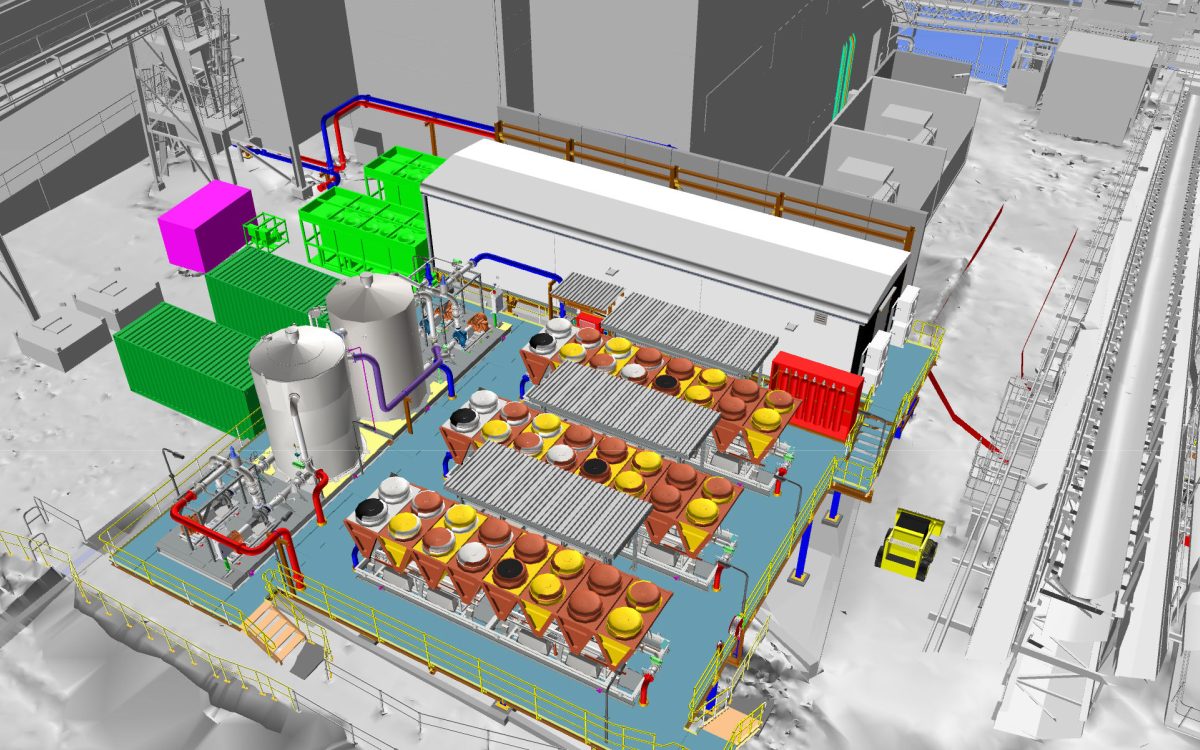

The project aimed to replace the cooling water supply systems for five grinding mills within the mine’s processing plant. This upgrade was critical to maintaining optimal operating temperatures, ensuring the safe, reliable, and efficient processing of gold and copper.

GPA provided engineering support during both the feasibility and detailed design phases, delivering the following key activities:

Feasibility Scope:

Assessment and specification of three independent chiller units feeding five separate grinding mills including:

- Calculation of required heat loads to appropriately size and specify vendor-supplied chillers.

- Development of multi-discipline layout to fit the chillers into existing site footprint.

- Identification of suitable electrical tie ins to power the chillers.

Detailed Design Scope:

Progression of the SAG & ML2004 Chilling system through to construction level detail including:

- Civil concrete and structural platform design to accommodate the chiller and switchroom installation.

- Mechanical and piping design for the water feed and return systems as well as the replacement of existing oil heat exchangers.

- Electrical design of a High Voltage tie in, transformer, switchroom and LV switchboard.

- Instrumentation design and control integration.

The project was executed within an active operational environment, requiring close collaboration with multiple stakeholders to manage the complexities of integrating new systems into existing infrastructure.

As the project progressed, the scope evolved, demanding a flexible and adaptive approach to planning and design to meet changing requirements.

The Cadia Chillers Upgrade Project highlights GPA Engineering’s capability to deliver complex, multidisciplinary engineering solutions in challenging brownfield environments—enhancing system performance and operational efficiency for our client.